ION EXCHANGE BASICS

Introduction

Ion exchange is a powerful chemical technology, little known to the general public. This simple page attempts to show what ion exchange is to those who are not chemical experts.

Ion exchange is a powerful chemical technology, little known to the general public. This simple page attempts to show what ion exchange is to those who are not chemical experts.

When my friends ask me what is my professional activity, I tell them "ion exchange". Most of them have no clue. In Western Europe, the majority of my friends have one or two ion exchange devices in their household. So, I return a question: "Why do you think you put salt in your dishwasher?" Very few know, and if you are in this case, you will discover why below.

Water

Water looks simple: it is made of water molecules (formula H2O). You know however that this apparent simplicity is more complex in reality: otherwise, bottled water producers would not make such a fuss about its mineralisation.

Water looks simple: it is made of water molecules (formula H2O). You know however that this apparent simplicity is more complex in reality: otherwise, bottled water producers would not make such a fuss about its mineralisation.

All natural waters contain some foreign substances, usually in small amounts. The water in the river, in a well or from your tap at home is not just H2O, it contains a little of:

- Solid, insoluble substances, such as sand or vegetal debris. You can in principle filter these solid substances out.

- Soluble substances, that you most often cannot see and that cannot be filtered out. These substances can be inorganic or organic, they can be ionised (electrically charged) or not ionised.

The soluble, non-ionised substances are present in the water in form of molecules of various sizes and formulas, for instance:

- Carbon dioxide is a small molecule with a simple formula: CO2.

- Sugar is a larger molecule with a complicated formula abbreviated as C12H22O11. Want to see the 3 D formula? Sugars are not removed by ion exchange, though.

You may want to remove these foreign substances from the water. You can remove the ionised substances by ion exchange.

Ions

The soluble, ionised substances are present in water as ions, which are electrically charged atoms or molecules. The positively charged ions are called cations, and the negatively charged ions are called anions. Because water is globally neutral electrically (otherwise you would get an electric shock when you put your hand in water) the number of positive charges is the same as the number of negative charges.

Ions can have one charge or more, the most usual range being 1 to 3. Ions can be made of one atom only (monoatomiic ions) , or several atoms linked permanently together, like molecules (polyatomic ions).

Examples:

- A monovalent monoatomic cation: the sodium ion Na+

- A divalent monoatomic cation: the calcium ion Ca++

- A monovalent polyatomic cation: the ammonium ion NH4+

- A monovalent monoatomic anion: the chloride ion Cl–

- A monovalent polyatomic anion: the nitrate ion NO3–

- A divalent polyatomic anion: the carbonate ion CO3=

- Another divalent polyatomic anion: the chromate ion (metallic complex) CrO4=

- The trivalent monoatomic aluminium cation Al+++ exists only in very acidic solution, not in normal water.

- Similarly, there are no monoatomic di or trivalent anions in normal water

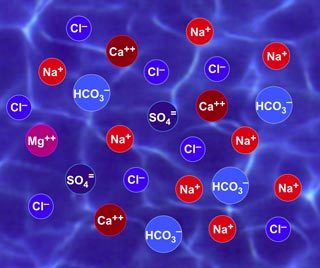

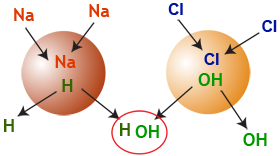

Ions are able to move around in water, they are not fixed, and they are not attached to ions of the opposite charge. Only the sum of the charges is the same for all cations and all anions. See figure 1 for a schematic representation of ions in water.

Figure 1: Ions in water are not attached to each other. The sum of charges is constant.

Salts are crystallised substances containing a fixed proportion of cations and anions. For instance, table salt has exactly the same number of sodium cations (Na+) and chloride anions (Cl–). Its formula is given as NaCl. When you dissolve a salt into water, its cations and anions are dissociated, and free to wander as seen on figure 1.

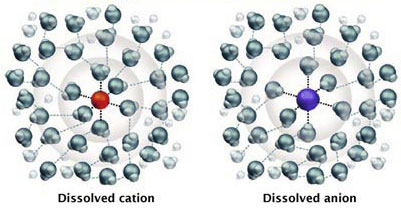

The dissolved ions are surrounded by water. They are said to be hydrated. They are loosely connected to water molecules, cations attracted by the O atom, anions by the H atoms of the water molecule, as shown in figure 2.

Ionic compound dissolved in water

Figure 2: Hydrated ions in water e.g. Na+ and Cl– (table salt NaCl)

Magnesium sulphate is a salt with exactly the same number of magnesium cations (with double charge: Mg++) and sulphate anions (also with double charge, SO4=) so that the formula is MgSO4.

Calcium chloride is made of calcium ions (with 2 charges, Ca++) and chloride ions (with 1 charge only, Cl–). You need 2 chloride anions to balance each calcium cation. Therefore the formula of calcium chloride is CaCl2.

Similarly, in sodium carbonate you have sodium cations Na+ and carbonate anions CO3=, so that you need 2 sodium ions for each carbonate ion, and the formula is Na2CO3.

When you boil and evaporate water for a long time, you are left with a dry residual which is made of salts and possibly other residues, such as silica and organic compounds. Only in sea water do you have a sizeable quantity of dry residual, 35 to 40 g dry residual for one litre of sea water. In river or tap water, the dry residual is usually very low, ranging from 50 to 500 mg/L. The dry residual is also called Total Dissolved Solids and abbreviated as TDS.

You may want to remove these foreign substances from the water. You can remove the ionised substances by ion exchange. See details of the water analysis and units of concentration used in ion exchange. What counts here is not the mass (g) nor the molarity (mol), but the "equivalent mass":

1 eq = 1 mol / valence

One mole of sodium (Na+) contains 23 g of the me;tal. As sodium is monovalent, one equivalent Na+ corresponds also to 23 g. But one mole of nickel (Ni++) contains 58.7 g metal, and one equivalent of Ni++ is thus only 29.35 g.

Ion Exchange

Impurities in water

Impurities? Water, as we have seen, contains small amounts of foreign substances. In many cases, these substances cause no problem, and should not be considered as impurities. Drinking water containing some salinity is much better for health than ultra-pure water. For specific applications, however, these foreign substances are regarded as impurities and must be removed from water.Insoluble substances (sand etc.) can be removed by filtration. There are many different sorts of filtration technologies, down to ultrafiltration that can remove sub-micron particles. For soluble substances other techniques must be used.

Soluble ionised substances can be removed by ion exchange.

Ion exchange resins

These are very small plastic beads, with a diameter of about 0.6 mm. These beads are porous and contain invisible water inside the beads, measured as “humidity” or “moisture content”. The structure of the resin is a polymer (like all plastics) on which a fixed ion has been permanently attached. This ion cannot be removed or displaced; it is part of the structure. To preserve the electrical neutrality of the resin, each fixed ion must be neutralised with a counterion. This counterion is mobile and can get into and out of the resin bead. Figure 3 shows a schematic cation exchange resin bead. The dark lines represent the polymeric skeleton of the resin bead: it is porous and contains water. The fixed ions of this cation exchange resin are sulphonates (SO3–) that are attached to the skeleton. In this picture, the mobile ions are sodium (Na+) cations. Cation exchange resins such as Amberjet 1000 are often delivered in the sodium form.

Figure 3: Schematic cation and anion resin beads

The anion resin bead has a very similar skeleton. The functional groups are here quaternary ammonium cations shown in the picture as N+R3; a more accurate formula would be CH2—N+(—CH3)3. Each ion going into the bead has to be replaced by an ion getting out of the bead, again to preserve electrical neutrality. This is what is called ion exchange. Only ions of the same electric sign are exchanged. You cannot make a resin that can exchange cations as well as anions, because the fixed cations inside the resin beads would neutralise the fixed anions and no exchange with the outside world would be possible. Therefore you need separate cation exchange resins and anion exchange resins.

Details about resin structure are given in a separate page.

Water softening

Among the substances dissolved in water, hardness is very commonly found. Hardness is a popular word to represent principally calcium and magnesium dissolved in the water; these ions can precipitate under certain conditions and form the scale that you may have seen in your boiling pan, and that can obstruct pipes and damage water boilers. The “softening” of water is the exchange of the hardness cations (Ca++ and Mg++) for another cation that cannot form scale because it is much more soluble: the sodium ion Na+.

To soften water, you take a cation exchange resin in which the mobile ion inside the beads is sodium (Na+) and you pass the hard water through a column filled with the sodium form resin. The hardness ions Ca++ and Mg++ move into the resin beads and each of these divalent cations is replaced by two sodium ions getting out of the resin. The exchange reaction can be written as:

2 RNa + Ca++  R2Ca + 2 Na+

R2Ca + 2 Na+

Figure 4 illustrates the reaction: the resin beads are initially loaded with sodium (Na+) ions. As shown schematically, each calcium or magnesium ion entering the resin bead is compensated by two sodium ions leaving it. Anions from the water cannot enter the resin bead because they would be repelled by the fixed sulphonate (SO3–) anions inside the beads.

Figure 4: Softening (sodium exchange) in a single resin bead

This cation exchange can only take place efficiently because the cation exchange resin has a higher affinity for the hardness ions than for sodium. In plain English, the resin prefers calcium and magnesium over sodium. The result of the softening process is not a net removal of the hardness ions from water, it is the replacement of the hardness ions by sodium ions. The salinity of the water has not changed, only the constituents of the salinity are different at the end of the softening process.

Obviously, this exchange is not unlimited: when the resin has removed so much hardness from the feed water that no room is left on the resin for removing more, the exhaustion run has to be stopped. At this stage, the resin will be replaced by a fresh resin, or regenerated.

Demineralisation

If you replace all cations dissolved in water by H+ ions and all anions by OH– ions, these will recombine and form new molecules of water. To do this, you need a cation exchange resin in the H form and an anion exchange resin in the OH form. All cations and anions will be exchanged, and in this case the net result is a complete “disappearance” of the ionic contaminants. The cation exchange reactions will be:

2 R’H + Ca++  R2Ca + 2 H+

R2Ca + 2 H+

R’H + Na+  R’Na + H+

R’Na + H+

In these equations, R’ represents the cation exchange resin. This is shown on figure 5. The resin is initially in the hydrogen (H+) form. In this picture the anions in water are not shown, but the sulphonic functional groups SO3– are. You can see that one Ca++ ion getting in causes two H+ ions to leave the resin, whilst one Na+ cation is exchanged for one H+ ion.

Figure 5: Decationisation (all cations replaced by H+)

Similarly, an anion exchange resin initially in the OH– form can remove all anions. The anion exchange reactions will be:

R’’OH + Cl–  R’’Cl + OH–

R’’Cl + OH–

2 R’’OH + SO4=  R’’2SO4 + 2 OH–

R’’2SO4 + 2 OH–

where R’’ represents the anion exchange resin. All anions are replaced by hydroxide (OH–) ions. There is no picture for this anion exchange, as it is very similar to the cation exchange picture in figure 5 above.

At the end of the exchange process, the resin beads have loaded all cations and anions from the water and released H+ and OH– ions. The resin beads are nearly exhausted (fig. 6).

These H+ and OH– ions will immediately combine and form water:

H+ + OH–  HOH

HOH  H2O

H2O

The ionic contaminants are now sitting on the two resins (Na and Ca on the cation resin, Cl and SO4 on the anion resin) and the water has been completely demineralised. Its salinity is reduced to almost nothing, a few ions that have “escaped” from the resin columns, and that are called ion leakage.

Figure 6: Resin beads are exhausted.

H+ and OH– ions have been released into the water

Water demineralisation can thus be summarised in a small single picture:

Figure 7: Demineralisation summary!

Regeneration

When the resins are exhausted, you can bring them back to the fresh state and start over again. Regeneration of ion exchange resins is a reversal of the exchange reactions shown above.

Regeneration of a water softener

The softening resin is regenerated with sodium (Na+) ions supplied by a salt (common salt: NaCl) solution. The regeneration reaction is:

R2Ca + 2 NaCl  2 RNa + CaCl2

2 RNa + CaCl2

Regeneration can only be performed when the concentration of the regenerant is high, typically 1000 times higher than the concentration in normal water. For instance, salt is used as a brine with 10 % (about 100 g/L) concentration.

Regeneration can only be performed when the concentration of the regenerant is high, typically 1000 times higher than the concentration in normal water. For instance, salt is used as a brine with 10 % (about 100 g/L) concentration.

At this stage, you will have understood why you put salt in your dishwasher: the salt is diluted with water and regenerates the invisible softening cartridge usually located at the bottom of the machine, out of sight.

Regeneration of a demineraliser

In the case of demineralisation, strong acids such as hydrochloric acid (HCl) or sulphuric acid (H2SO4) are fully dissociated and can supply H+ ions to replace the cations that have been exchanged and are sitting in the cation exchange resin beads at the end of the exhaustion run:

R’Na + HCl  R’H + NaCl

R’H + NaCl

Similarly, strong alkalis, of which in practice only caustic soda (NaOH) is used, can supply OH– ions to replace the anions sitting on the anion exchange resins beads at the end of the run:

R’’Cl + NaOH  R’’OH + NaCl

R’’OH + NaCl

As can be seen from the regeneration reactions, the regeneration step produces saline waste. This is the principal disadvantage of ion exchange.

See the desciption of a complete cycle and a page with co-flow and reverse flow regeneration methods.

How resins look like

Click on the pictures

A sample of AmberliteTM FPC23 |

AmberjetTM mixed bed resins |

AmberjetTM 4400 |

There is a full page with many other resin pictures under the microscope.

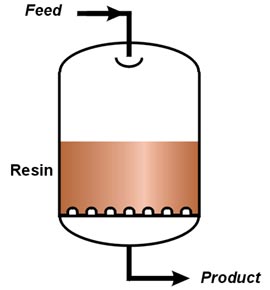

Column operation

In the laboratory as well as in industrial plants, ion exchange resins are used in columns. The water or solution to be treated flows through the resin. On the picture at the right, you see the fresh resin, then you see how the resin gets progressively loaded with the ions from the feed solution. Ions from the resin — not shown on the picture — are released into the treated solution. At the end some of the ions from the feed escape into the pure solution, and operation is stopped.

In the laboratory as well as in industrial plants, ion exchange resins are used in columns. The water or solution to be treated flows through the resin. On the picture at the right, you see the fresh resin, then you see how the resin gets progressively loaded with the ions from the feed solution. Ions from the resin — not shown on the picture — are released into the treated solution. At the end some of the ions from the feed escape into the pure solution, and operation is stopped.

The next pictures show a typical laboratory column, a simple industrial column and a photograph of an existing Amberpack plant.

|

|

|

| Laboratory setup | Industrial column | AmberpackTM column |

The jug showed at the top of this page contains a small filter filled with activated carbon and ion exchange resin. The quantity of resin is around 150 ml. For comparison, a large industrial ion exchange column can contain 20'000 L of resin, sometimes more.

Ion exchange capacity

Total capacity

The number of "active groups", or "functional groups" in an ion exchange resin is its total capacity. As there are billions of individual active groups in a single bead of resin, the capacity is usually expressed in equivalents per litre of resin. One equivalent is 6.02×1023 active groups. You don't have to remember this very large number called Avogadro number.

A typical strong acid cation exchange resin has a total capacity of 1.8 to 2.2 eq/L

A typical weak acid cation exchange resin has a total capacity of 3.7 to 4.5 eq/L

A typical weak or strong base anion exchange resin has a total capacity of 1.1 to 1.4 eq/L

Operating capacity

In the "column operation" picture above, the resin is 100% regenerated at the beginning of the run, and not completely exhausted at the end of the run. The definition of operating capacity is: the difference of regenerated sites between the beginning and the end of the ion exchange run. It is also measured in equivalents per litre.

In operation, the operating capacity of the resin amounts to about half the total capacity. The actual range is 40 to 70 % of the total capacity depending on the operating conditions. See other details in a specific page.

It is the number of ions and their charge (one, two, or three charges per ion), not their mass or weight, that is important for ion exchange. Therefore all feed water analyses must have the mass of ions converted to equivalents.

It is the number of ions and their charge (one, two, or three charges per ion), not their mass or weight, that is important for ion exchange. Therefore all feed water analyses must have the mass of ions converted to equivalents.Why the resin quantity is expressed in volume, not weight

When an ion exchange resin filter is designed and built, it is the volume of filtering media that is important to determine the column size, not its mass. Ion exchange resins have different density values (see resin properties), so the resins are sold by volume, in litres or cubic metres, or in cubic feet in the USA. Many of the resin properties are also related to the resin volume.

Treated water quality

In a typical demineralisation system regenerated in reverse flow (see regeneration methods), the treated water quality, expressed in water conductivity, is below 1 µS/cm. Considering that feed water from rivers and deep wells has a conductivity of 100 to more than 1000 µS/cm, the efficiency of ion exchange ranges from 99 to more than 99.9 %. Other processes, such as reverse osmosis, are far from this high salt rejection number.

Limits of ion exchange

For ion exchange to be efficient there must be a difference in affinity between the ion in the resin and the ion or ions you want to remove from solution. The resin must have a higher affinity for the ion in solution compared to the ion in the resin.

The ion exchange technology is a perfect tool to remove or exchange contaminants present in low concentrations. In such a case the running time until the resin column is exhausted can be very long, ranging from a few hours to several months. When however the concentration of contaminants is high, say several grams per litre of water, the ion exchange cycles become exceedingly short and the quantity of regenerants increases to uneconomical levels. In the case of brackish water (underground water with high salinity as often found in arid countries) or sea water, ion exchange is not suitable and other technologies must be used, such as reverse osmosis or distillation.

Also, any contaminant that is not ionised cannot be removed by ion exchange. Other technologies are available for this purpose, using activated carbon, polymeric adsorbents, molecular sieves and other media.

Selective ion exchange

Thanks to differences of affinity for different ions, common ion exchange resins can be used to remove selectively ions from water. One of the most obvious examples is softening. You cannot soften water effectively with reverse osmosis — i.e. remove only Ca++ and Mg++ ions: RO is not selective and will remove Na+ ions as well; only ion exchange can soften water with a cation exchange resin in the Na+ form. Similarly, you can remove fairly selectively other ions from water, such as nitrate of sulphate, using an anion exchange resin in the chloride form. This works because the anion exchange resin has more affinity — or a better selectivity — for the nitrate or sulphate ion than for the chloride ion, the order of affinity being:

SO4= > NO3– > Cl– > HCO3– > OH– > F–

There is thus no practical way — with any technology — to remove only chloride from water without removing other anions as well.

For cation resins used in softeners, the affinity is

Pb++ > Ca++ > Mg++ > Na+ > H+

The Pb (lead) is shown here to indicate that any dissolved lead will be removed efficiently by a softening resin, as well as many other (but not all) heavy metals. See tables of selectivity values for cation and anion exchange resins.

Some contaminants are not easy to remove by conventional ion exchange resins. In many cases, very specific resins have been developed for these contaminants. Selective resins are available today for the removal of:

- Boron

- Nitrate

- Perchlorate

- Nickel

- Chromate

Outside of water treatment

There is an incredible number of applications in fields other than water treatment. Let us mention a few of them:

- Softening of beet sugar juices before evaporation

- Colour removal from cane sugar syrups

- Chromatographic separation of glucose and fructose

- Demineralisation of whey, glucose and many other foodstuffs

- Recovery of polyphenols for use in the food industry

- Recovery of uranium from mines

- Recovery of gold from plating solutions

- Separation of metals in solution

- Catalysis of anti-knocking petrol additives

- Extraction of antibiotics and other compounds from fermentation broths

- Purification of organic acids

- Powdered ion exchange resin is used in tablets in the pharmaceutical industry

Conclusion

Ion exchange is a very powerful technology to remove impurities from water and other solutions. Many industries depend on ion exchange for the production of extremely pure water. Examples are:

Ion exchange is a very powerful technology to remove impurities from water and other solutions. Many industries depend on ion exchange for the production of extremely pure water. Examples are:

- Nuclear and thermal power stations

- Semiconductor, computer chips and display panel production

- Selective removal of toxic contaminants from drinking water

Go to the site map for several detailed pages on applications, processes, resin properties and more.

Amberjet, Amberlite, and Amberpack are original trademarks of Rohm and Haas, a subsidiary of the Dow Chemical Company.